Diamond

saccharomyces carlsbergensis

Origin

Diamond Lager yeast originated in Germany and is used by a number of commercial breweries to produce different types of lager. The propagation and drying processes have been specifically designed to deliver a high quality beer yeast that can be used simply and reliably to help produce lagers of the finest quality. No colours, preservatives or other unnatural substances have been used in its preparation. The yeast is produced in ISO 9002 certified plants.

Microbiological Properties

• Classified as Saccharomyces carlsbergensis (new taxonomy: Saccharomyces pastorianus)

• A bottom fermenting yeast

• The typical analysis of the active dried strain:

|

Percent solids Living yeast cells Wild yeast Bakterien gesamt |

93 - 95 % ≥ 5 x 109 per gram of dry yeast < 1 per 106 yeast cells (Lysine method)* < 1 per 106 yeast cells* |

• Finished product is released to the market only after passing a rigorous series of tests

*According to ASBC and EBC methods of analysis.

Brewing Properties

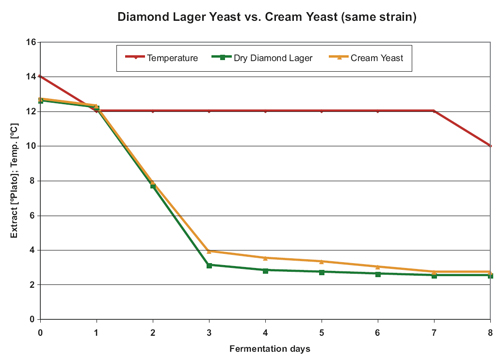

Quick start and vigorous fermentation, which can be completed in 5 days above 12°C.

High attenuation.

Fermentation rate, fermentation time and degree of attenuation depend on inoculation density, yeast handling, fermentation temperature and the nutritional quality of the wort.

Flocculent strain; settling can be promoted by cooling and use of fining agents and isinglass.

The aroma and taste are almost neutral and do not display off-flavours when properly handled. It may tend, because of flocculation, to slightly reduce hop bitter levels.

Best used at traditional lager temperatures (10-15ēC) after rehydration in the recommended manner.

Usage

When 200 g active dried yeast is used to inoculate 100 litres of wort a yeast density of 10-20 million cells per millilitre is achieved. Brewer may experiment with the pitching rate to achieve a desired beer style or to suit processing conditions.

Sprinkle the yeast on the surface of 10 times its weight of sterilized/boiled tap water or diluted wort (2-6°P) at 25-30°C. (NB: Do not use distilled or reverse osmosis water as loss in viability might result.) GENTLY break any clumps to ensure that all yeast is in contact with the rehydration medium. DO NOT STIR. Leave undisturbed for 15 minutes, then suspend the yeast completely and leave it for 15 to 45 more minutes at 20-30°C. Then adjust temperature to that of the wort and inoculate without delay.

Attemperate by blending portions of wort in 10 minute intervals, less than 10°C at a time. Do not allow attemperation to be carried out by natural heat loss. This will take too long and could result in loss of viability or vitality.

Temperature shock, at greater than 10ēC, will cause formation of petite mutants leading to long-term or incomplete fermentation and possible formation of undesirable flavours.

Diamond Lager yeast has been conditioned to survive rehydration. Dry yeast contains an adequate reservoir of carbohydrates and unsaturated fatty acids to achieve active growth. It is not necessary to aerate wort when dry yeast is used.

Storage

All active dried yeast should be stored dry and below 8°C. The packaging should remain intact.

Activity loss is about 25% per year at 8°C and 50% per year at 22°C in unopened sealed packs.

Diamond Lager yeast will rapidly lose activity after exposure to air. Do not use 500 g or 10 kg packs that have lost vacuum. Opened packs must be re-closed, stored in dry conditions below 4°C, and used within 3 days; 11 g sachets are not vacuum packed, but are flushed with nitrogen gas to protect the yeast.

Do not use yeast after expiry date printed on the pack.

LALLEMAND NATURAL BREWING YEAST

SO EASY TO STORE Active dried lager yeast has a shelf life of 1 year if stored below 8°C.

SO EASY TO USE Follow simple rehydration instructions and addition rates.

SO INTERNATIONAL Used in hundreds of breweries in Britain, U.S,A., Canada, Japan, South America and worldwide.